NXCT at the Centre for Imaging Metrology and Additive Technologies

The Centre for Imaging Metrology and Additive Technologies (CiMAT) is based within Warwick Manufacturing Group (WMG) at the University of Warwick with a history in product evaluation using a variety of characterisation techniques, manufacturing and 3D visualisation. Situated in the West Midlands we are among a hotbed of high-value manufacturing, particularly automotive, with partners such as Jaguar Land Rover, TVS and the UK Battery Innovation Centre. While this is our core focus, our skills have been applied across a variety of sectors to include archaeology with the Oxford University Museum of Natural History and forensics with the West Midlands Police.

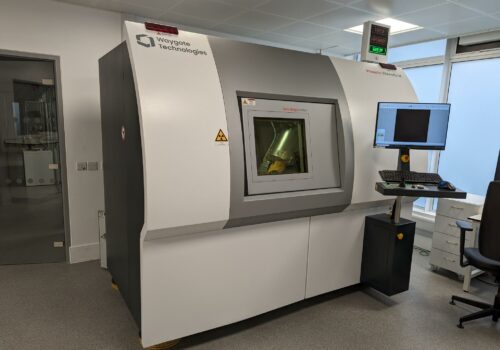

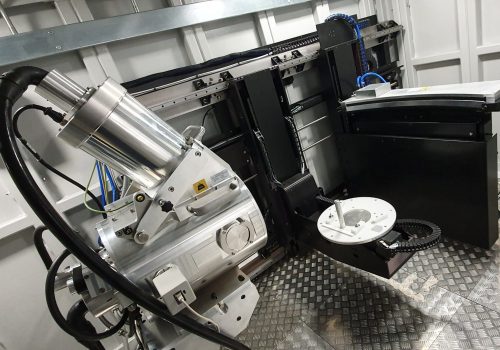

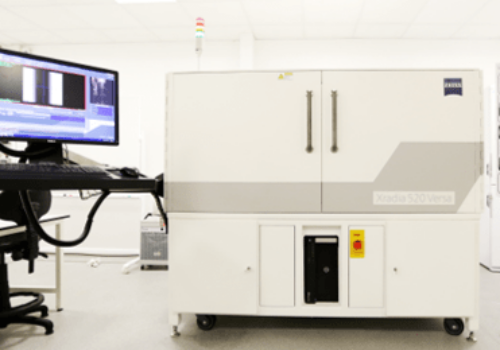

The facility consists of five on-site X-ray Computed Tomography scanners, an analysis suite with 14 high-powered workstations with proprietary software and a visualisation room for fully immersive 3D interrogations. This is complemented by a number of Co-ordinate Measurement Machines for metrology, providing correlative measurement and confidence in your results. Where a scale replica of a scanned item is required there is a range of additive manufacture equipment on-site for 3D printing objects.

The hosted equipment enables non-destructive observation of internal structures of objects varying in size from full assemblies down to resolutions for the characterisation of novel materials. Where in-operando degradation or changes due to loading (e.g. force, temperature, electrical) occur in a sample, our high-speed scanner is particularly suited for these observations with full tomographic scans possible in 10’s of seconds in certain conditions.

We welcome both academic and industrial collaborations, at any stage in your imaging process – from identifying appropriate scanning procedures and experimental design through to measurement and visualisation. We have experience in imaging across a variety of disciplines to include measurement, manufacturing, archaeology, forensics, materials and biomedical. Further where you own your own CT scanner and want to achieve the best from it, we can organise bespoke training for its use and data analysis.

Examples of outputs from typical scanning experiments may include:

• 2D slices and 3D visualisations

• Surface and volumetric meshes

• Export for 3D printing

• Dimensional Measurements

• Porosity analysis

• Actual/nominal comparisons with CAD

• Wall thickness analysis

• Strain and displacement analysis from dynamic experiments (DVC)

Every scan and experiment is unique, and through discussion with our experts we are able to design bespoke analysis to fit your needs.