3D Microstructure of Soft Magnetic Elastomer Membrane

Soft magnetic elastomer membranes enable fast magnetic actuation under low fields. In our project, we… Read More

Events & Resources

News, Events and Resources from NXCT Partners

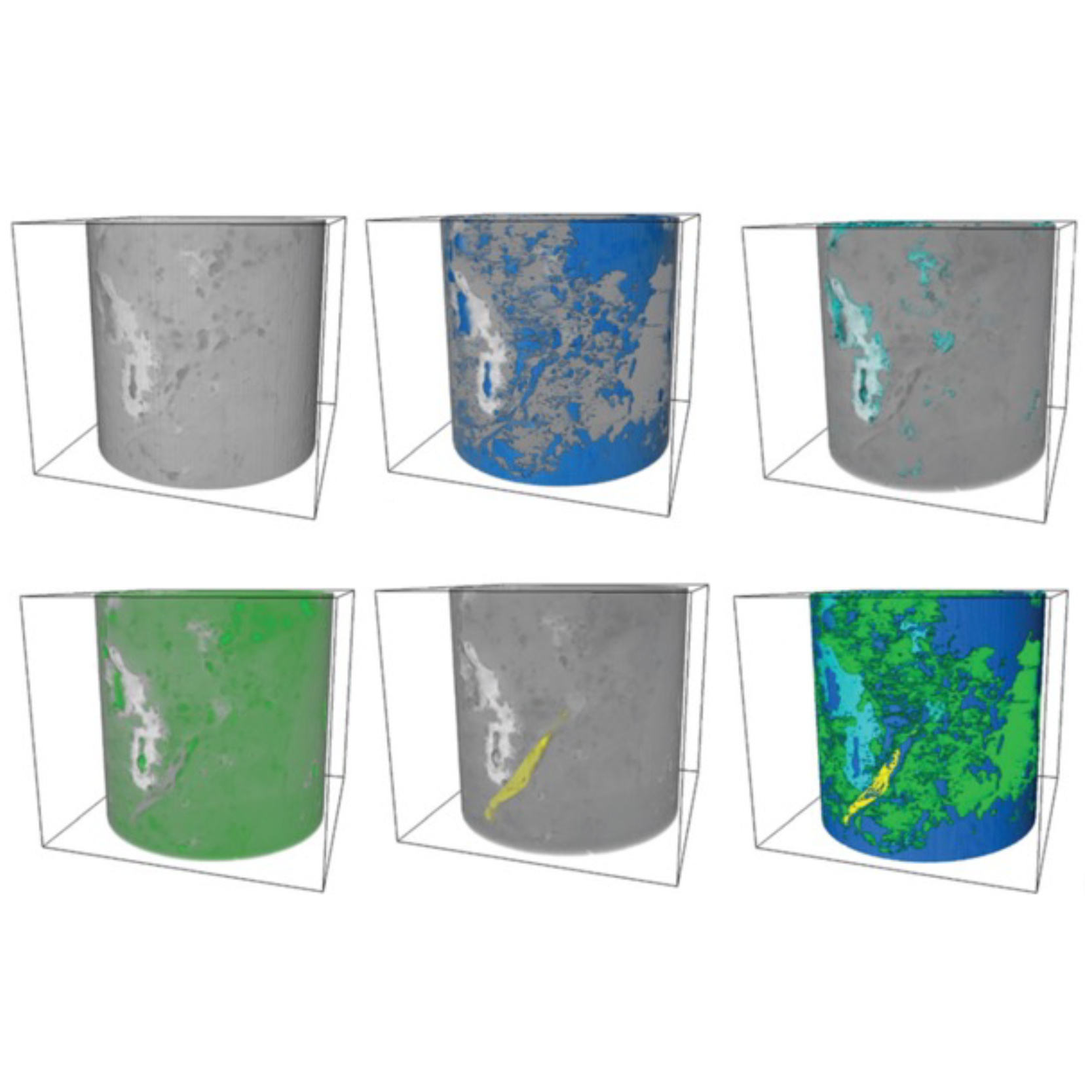

The aim of this project is to investigate the origin of cracks produced during Aluminium sheet bending. Samples from two manufacturing schedules and two load directions were XCT scanned at different stages of bending to find differences in the propensity to early failure during bending due to crack initiation at the external surface of the bent region. The samples were bent to different bending angles and scanned to observe the crack initiation and track the evolution of the microstructural inhomogeneities around the cracks as bending advances.

When bending is applied to Al sheets, early failure may appear at the external surface deformed in

tension. The cause is still unknown, but it has been observed that one additional step in the manufacturing process is reducing the damage, especially when the bending is applied in a particular direction. Samples from both manufacturing conditions were bent and XCT scanned at different bending angles to compare how voids and particles evolve with bending and how cracking starts in both manufacturing conditions, when bending along two different directions are applied (rolling and transversal directions).

It is of vital importance to understand the role that the microstructural inhomogeneities have on the bending performance of the material studied. The results from the XCT reconstructions comprise 4 samples in total at 4 stages of bending. The particles and voids were thresholded and their evolution along with bending were tracked. The expertise from the researchers supporting this project at the NXCT centre allowed the correct selection of the equipment and to set the optimal parameters to capture a significant volume of sample but ensuring enough resolution to capture as much inhomogeneities in the microstructures as possible. The availability of computers with large capacity and the licenses for the reconstruction and 3D analysis of the XCT datasets eased the data processing with the support of the experts at the NXCT centre.

The XCT scans performed with Zeiss Versa 620 benefited this research as it is a non-destructive and fast technique that allows automatise the consecutive scan of the four samples in one single session. XCT provides accurate 3D information of the microstructural inhomogeneities without the risk of producing damage to the samples that could interfere with the bending experiment or the particles and voids statistics.

The studied alloy is widely applied in the automotive sector as external panels of vehicles. The future impact of this research includes producing high quality Al sheets with improved final performance, formability and longer durability, by means of connecting their microstructure with their resistance to surface cracking during bending. Improved Al sheets imply that heavier materials like steel can be more easily substituted by Al sheet, reducing the weight of the vehicles, which reduces the petrol consumption and the emissions to the atmosphere.

“In the automotive sector, the substitution of heavier parts for lighter aluminium alloys reduces the weight of the vehicles, which is traduced to not only to higher velocity with less consumption, but also to fewer emissions to the atmosphere. One current limitation of aluminium alloys is their bendability. If an explanation of what is happening to the aluminium microstructure during bending is found, their manufacturing can be tailored to optimise their microstructure and improve their bendability. It is of vital importance to keep investigating the aluminium alloys properties and tailoring their manufacturing accordingly, so they can remain competitive in the market and replace heavier materials used in the automotive sector.”

Laura González Duque, University of Manchester PhD candidate

Collaborators: Prof. João Quinta da Fonseca, Prof. Joseph Robson, Dr. Elisa Cantergiani, Dr. Zeqin Liang, Dr. Christian Leppin

Figure 1: Example of scanned bent sample at the initial stage of bending

Figure 2: Cross section showing all the thresholded particles. They are far from the tensioned (top) and compressed (bottom) surfaces.

Figure 3: Cross section showing all the thresholded voids. They are at the surface loaded in tension.

Soft magnetic elastomer membranes enable fast magnetic actuation under low fields. In our project, we… Read More

Nowadays, the increasing capability of micro-manufacturing processes enables the manufacture of miniature products with extremely… Read More

Injection of CO2 into shale reservoirs to enhance gas recovery and simultaneously sequester greenhouse… Read More