3D Microstructure of Soft Magnetic Elastomer Membrane

Soft magnetic elastomer membranes enable fast magnetic actuation under low fields. In our project, we… Read More

Events & Resources

News, Events and Resources from NXCT Partners

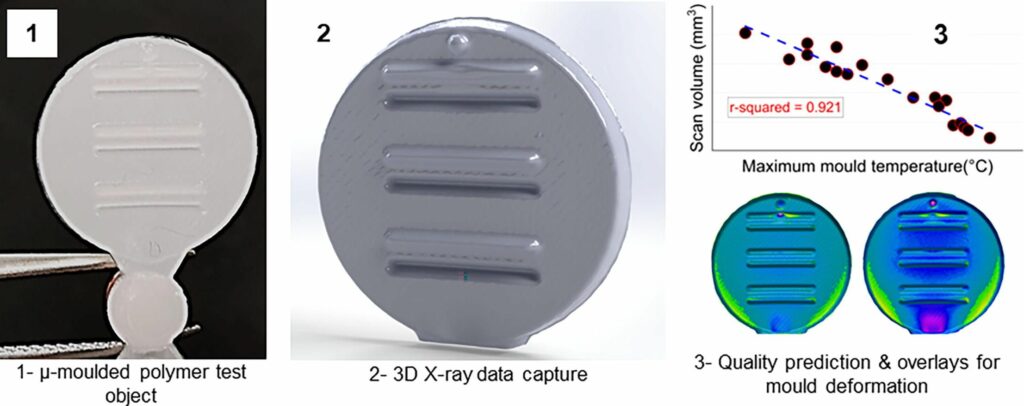

Nowadays, the increasing capability of micro-manufacturing processes enables the manufacture of miniature products with extremely small dimensions, complexity, and net-shape for a wide range of applications. With this in mind, the quality assurance procedures of micro and nano featured products also become very challenging and innovative methods have to be developed. The motivation of this work was to utilise extensive XCT capability at Warwick for evaluating it for the quality assurance procedures of micro-manufacturing processes. Specifically, micro-injection moulded miniature test objects that has micro-geometries were prepared and scanned using state-of-the-art XCT technology.

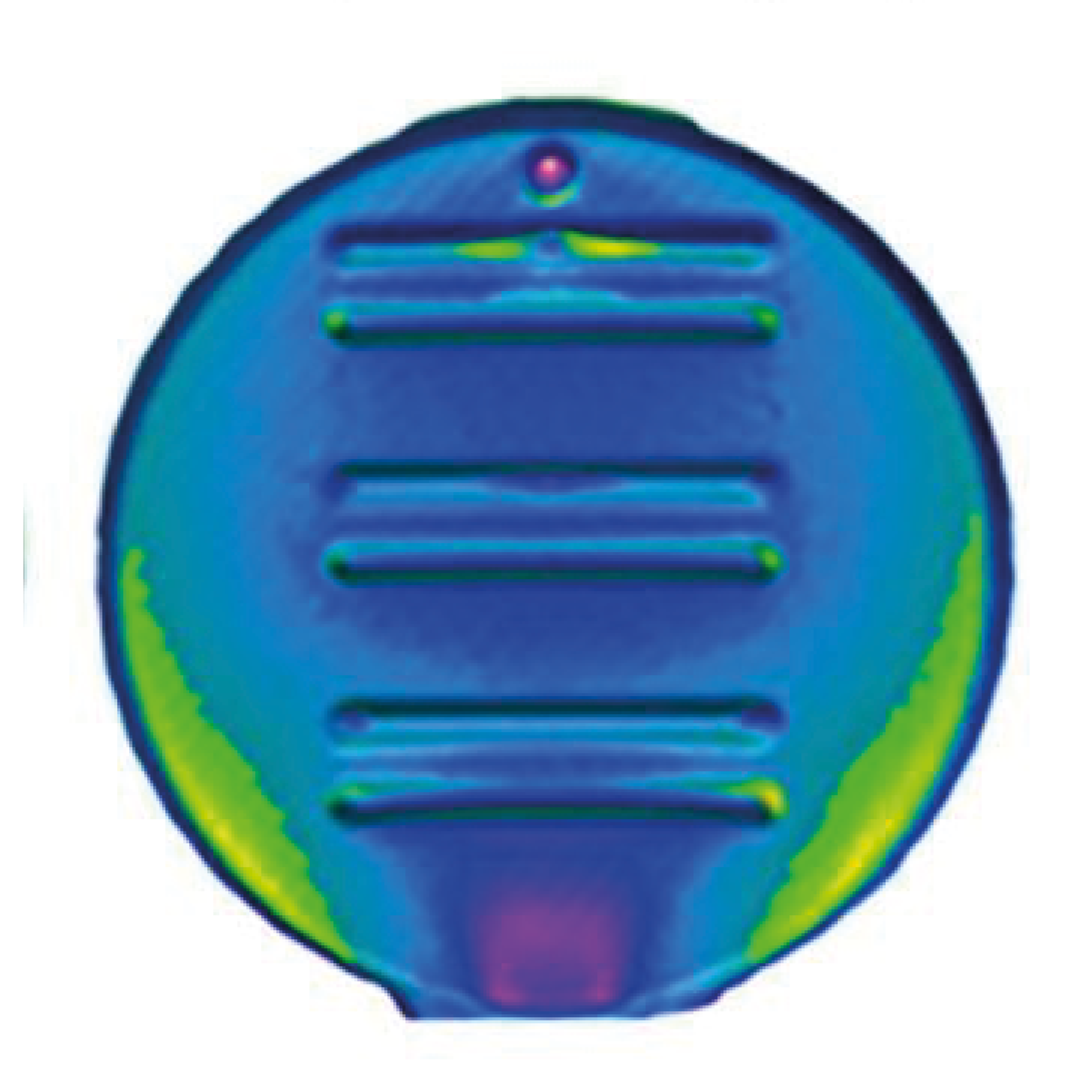

The work also had a rapid prototyping process evaluation aspect, where 3D printed moulds were used during micro-injection moulding. Hence, the 3D XCT data coming from polymer mouldings were successfully utilised in creation of a “predictive modelling” of micro-injection moulding process quality with a 92% accuracy. Moreover, deformations on the 3D printed mould inserts were also evaluated in extensive overlaying and 3D visualisation methods. The XCT data was also compared against as state-of-the-art laser-scanning confocal microscope for validation.

NXCT’s free access scheme has been instrumental for implementation of this research and publishing an impactful paper. The work brought together different funding sources such as EPSRC and High-Value Manufacturing Catapult at WMG and enabled showcasing our excellent capabilities in metrology and manufacturing.

We have been the first research group to implement XCT for predictive quality monitoring for manufacturing applications, hence, we expect that our paper will be a highly-cited exemplary scientific work in the coming years. The experiment demonstrated is not only a rigorous scientific work, but also applicable to industry to make a wider impact and expand the usage of X-ray CT scanning.

We already plan future papers to push the 92% quality prediction accuracy of the XCT systems, and applying this unique 3D visualisation capability of for other additive manufacturing processes.

“X-ray CT has a very big potential to be used in predictive modelling of micro-manufacturing processes where the quality assurance of products requires expensive methods, time and labour. It was an excellent experience to conduct this collaborative research and demonstrate NXCTs capabilities for the first time in the scientific literature for the predictive quality monitoring.”

Dr Mert Gulcur, WMG, University of Warwick, Lead Engineer

Soft magnetic elastomer membranes enable fast magnetic actuation under low fields. In our project, we… Read More

Nowadays, the increasing capability of micro-manufacturing processes enables the manufacture of miniature products with extremely… Read More

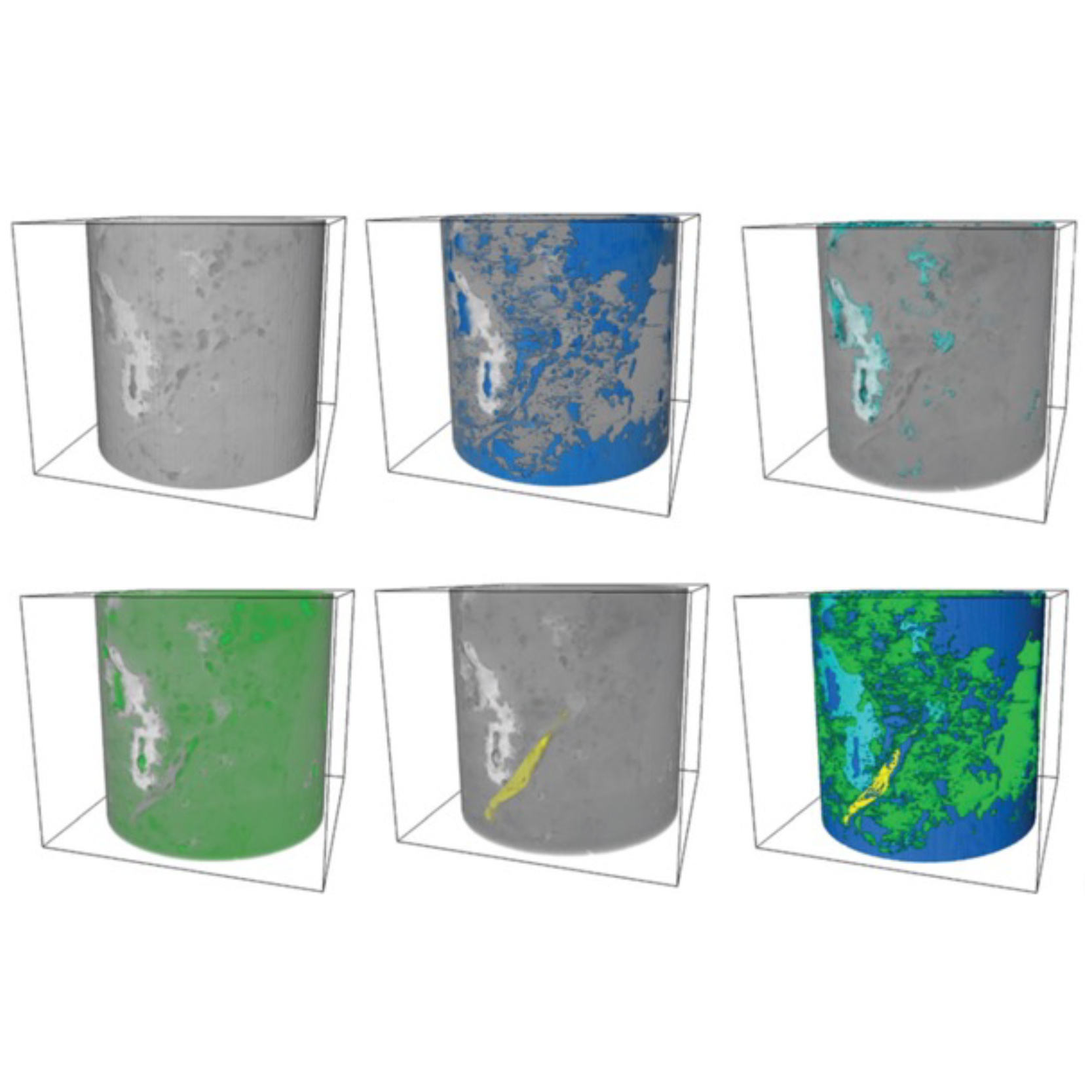

Injection of CO2 into shale reservoirs to enhance gas recovery and simultaneously sequester greenhouse… Read More