3D Microstructure of Soft Magnetic Elastomer Membrane

Soft magnetic elastomer membranes enable fast magnetic actuation under low fields. In our project, we… Read More

Events & Resources

News, Events and Resources from NXCT Partners

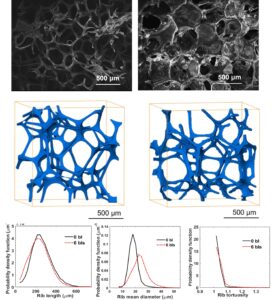

Prepared with nanoclays-polymer coatings, flexible polyurethane foam composites show improved energy absorption and damping properties for high-end applications, like aerospace, automotive and building. With this project at NXCT, the aim was to obtain the 3D topology with extraction of topologic parameters of the coated composites.

Flexible polyurethane (PU) foam composites could be made from to enhance the mechanical properties and serve more purposes, such as energy absorption and damping in aerospace, automotive and buildings. Nanoclay coatings could be designed and fabricated to prepare a composite in a facile layer-by-layer assembly method with the aim of mechanical improvement.

Sepiolite/chitosan coating layers were built and coated successfully throughout the foam skeleton, with a significant improvement of stiffness, energy absorption, vibration damping and impact resistance.

The structure of the PU composites was observed using SEM first, which gave a clear morphology while a 3D view of foam cells was lacked. Therefore, NXCT allowed to obtain enough topologic information which gave not only a clear spherical look of the specimen, but also adequate data base to extract key topologic parameters, e.g., the mean rib diameter, length, tortuosity and porosity, which made it possible to systematically compare the specimens. This gave important information for further structural mechanical analysis.

This work provided a simple and effective method for PU foam composites preparation for enhanced mechanical and damping performances in PU foam applications. In future, more research will be done on optimising the effect from the coating layers. This involves the choices of coating materials, coating methods, morphology and the investigation of mechanical improvements of the newly prepared composites.

“I would like to give my sincere appreciations to NXCT facility who have helped the work with professional testing and the answers to all questions I had. With the EPSRC grant, we managed to investigate the topology of the designed composites, which is crucial to the research of PU foam-coatings and high energy-absorbing materials.”

Wenfei Ji, PhD student, School of Chemistry, University of Bristol

Soft magnetic elastomer membranes enable fast magnetic actuation under low fields. In our project, we… Read More

Nowadays, the increasing capability of micro-manufacturing processes enables the manufacture of miniature products with extremely… Read More

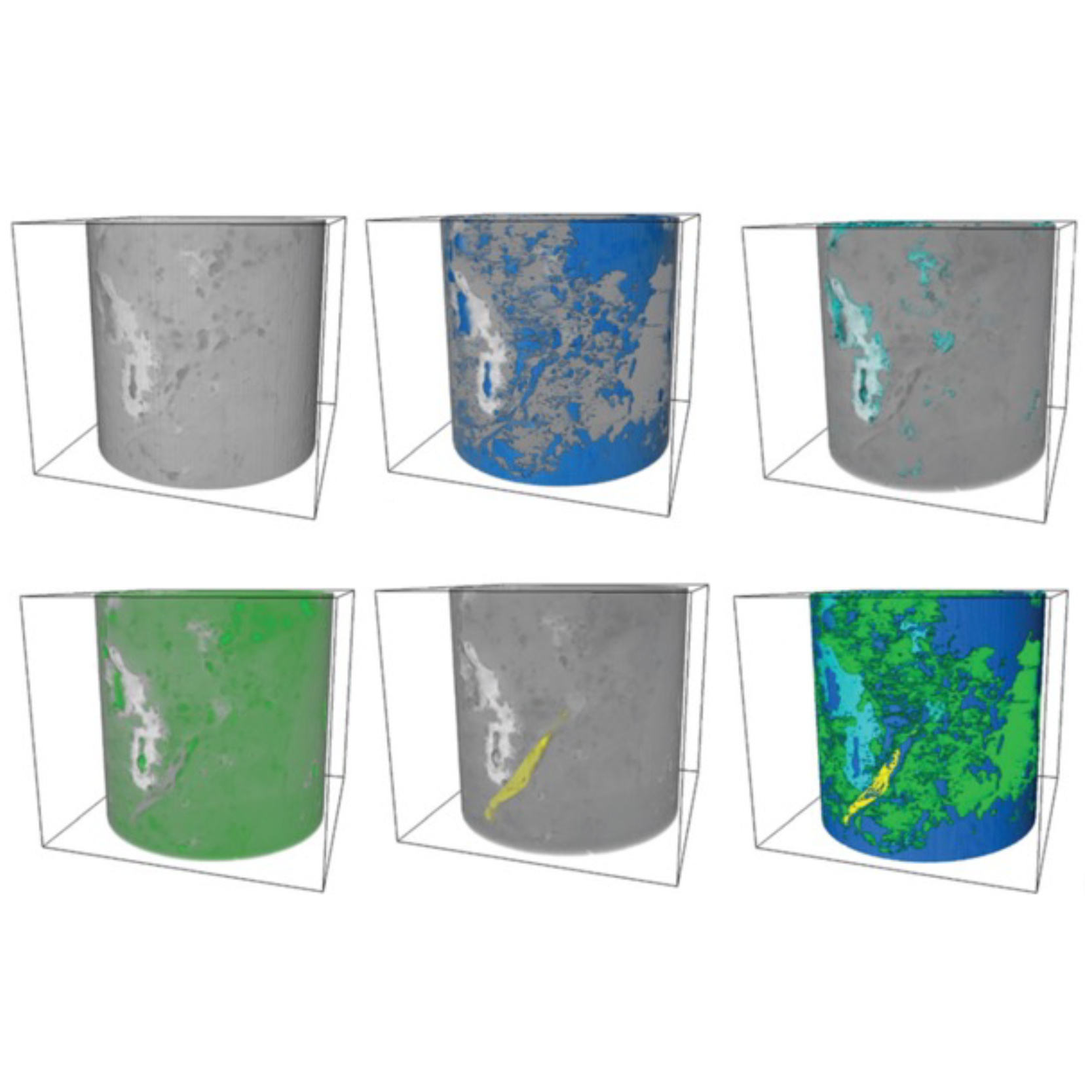

Injection of CO2 into shale reservoirs to enhance gas recovery and simultaneously sequester greenhouse… Read More