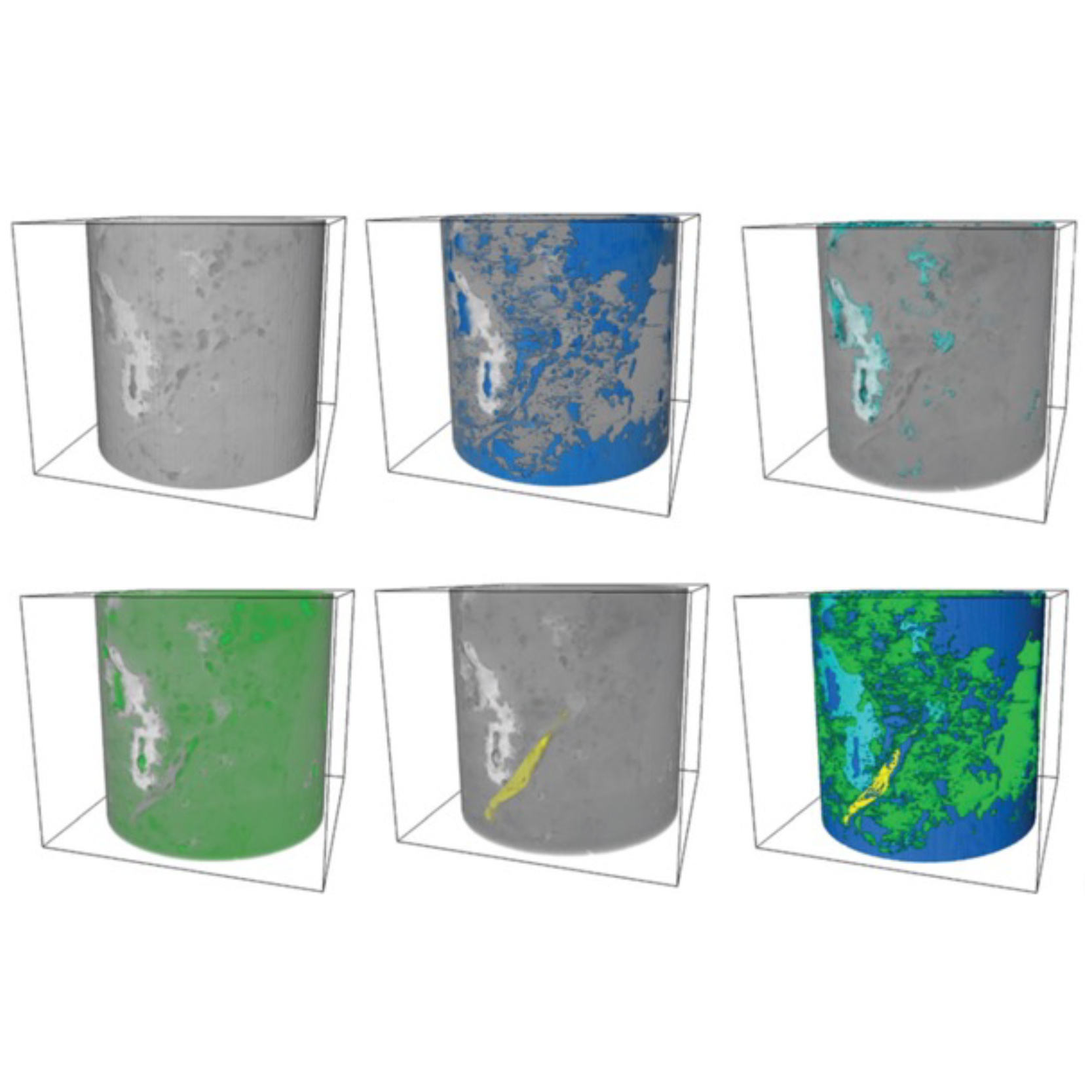

3D Microstructure of Soft Magnetic Elastomer Membrane

Soft magnetic elastomer membranes enable fast magnetic actuation under low fields. In our project, we… Read More

Events & Resources

News, Events and Resources from NXCT Partners

Through X-ray CT we are helping to uncover the ideal baking time, thickness and recipe for the ultimate eating experience: biscuits were baked inside the system in a bespoke oven to analyse their structure and find how the “perfect crunch” forms.

Models of biscuit baking processes currently use idealised initial conditions related to shape, temperature and recipes. In reality, the biscuit is non-uniform both in shape, ingredient distribution and temperature gradients/changes during the baking process. This leads to a strong difference between the models and reality. To improve these models, it is useful to have more information on what happens during the bake resulting from these irregularities. In situ XCT is a good option to study this but there are some challenges to overcome: designing an oven that can be used in a laboratory XCT system and obtaining an acceptable time resolution to follow the changes during the baking process.

For this project a convection oven was designed that could be used within the XCT system. Although the project time was limited, it required to design a convection oven suitable to both bake biscuits representative of the industrial process and to use within a XCT system; requirements included being made of low density but heat resistant materials, as small as possible to minimise scan geometry and able to reach at least 160°C. The final oven used an off the shelf convection oven connected to a box of heat resistant material put on a frame to isolate the rotational movement during the scan.

Besides using the TESCAN UnitomXL system that allows fast scanning, also iterative reconstruction was implemented to be able to scan the biscuit every 20 seconds. An interesting observation that was supported by measurements was that the biscuit rose quickly during the first part of the bake and then collapsed slowly during the second part of the bake.

This work showed is possible to study biscuit baking processes in situ with XCT and helped to understand what happens during the baking process and will help to model this process. There are different improvements that could be made for future projects including the designing a smaller oven, placement of the biscuits and implementation of more advanced image processing methods.

Click here to read more about the study.

Soft magnetic elastomer membranes enable fast magnetic actuation under low fields. In our project, we… Read More

Nowadays, the increasing capability of micro-manufacturing processes enables the manufacture of miniature products with extremely… Read More

Injection of CO2 into shale reservoirs to enhance gas recovery and simultaneously sequester greenhouse… Read More