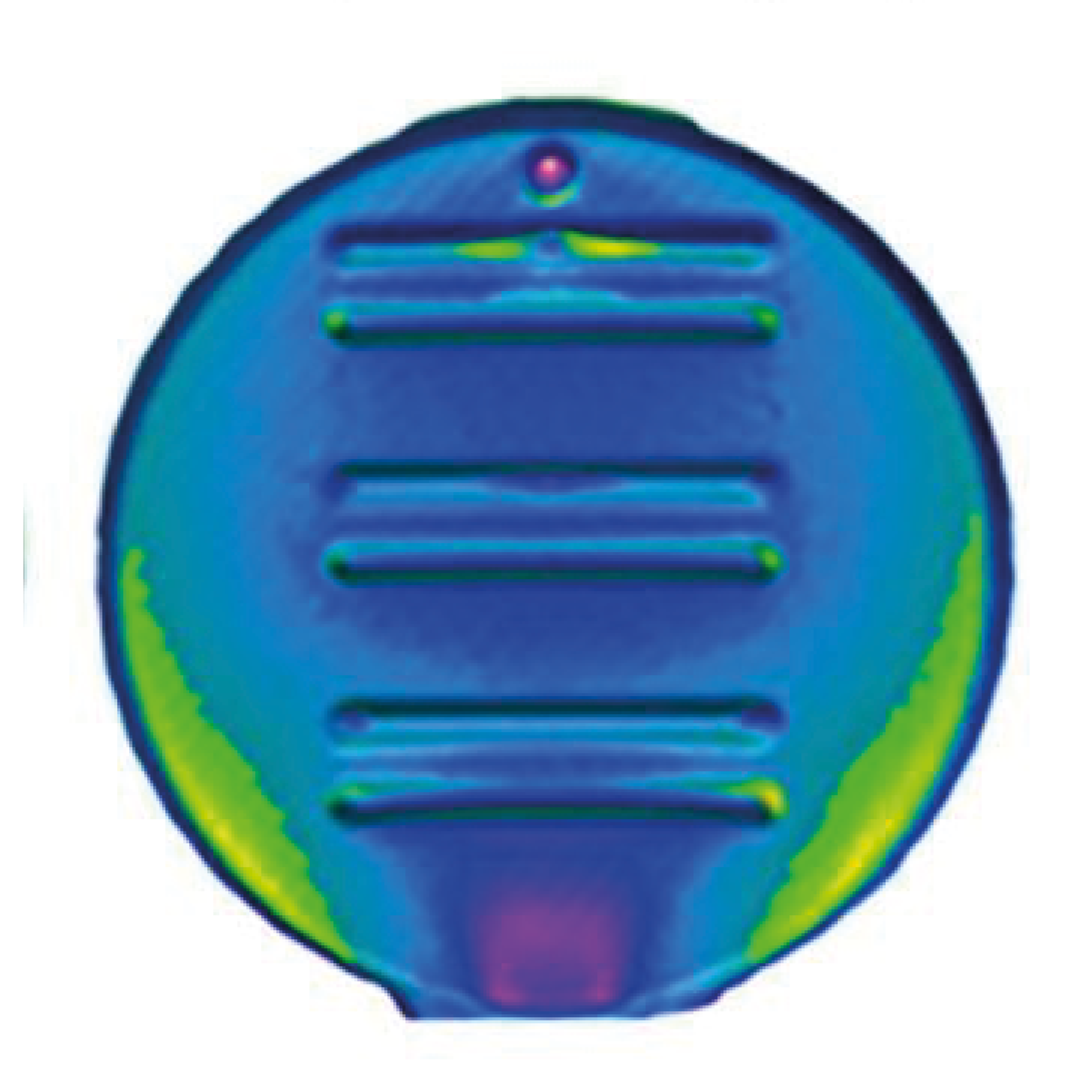

3D Microstructure of Soft Magnetic Elastomer Membrane

Soft magnetic elastomer membranes enable fast magnetic actuation under low fields. In our project, we… Read More

Events & Resources

News, Events and Resources from NXCT Partners

The analysis of the failure mode is of utmost importance to promote a greener transportation system with lighter and more damage-tolerant composite structures. Thanks to their improved recyclability and higher toughness, unidirectional carbon-fibre reinforced thermoplastic materials are recently emerging as one of the main alternatives to thermoset composites for aircraft structures. A full understanding of this new class of material would allow for a safer and eco-friendly design. Within this framework, a detailed analysis of the main degradation mechanisms involved in the longitudinal fracture of these material was carried out with the NXCT support. Double-edge notched specimens, typically used for the characterization of the longitudinal fracture properties of composite materials were tested and some of the coupon CT scanned.

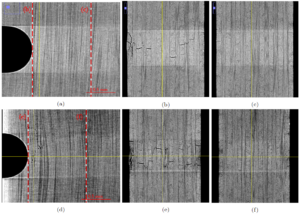

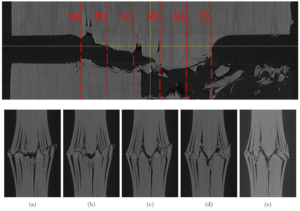

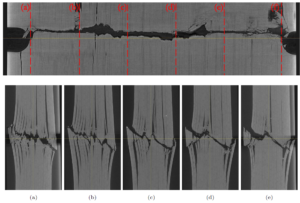

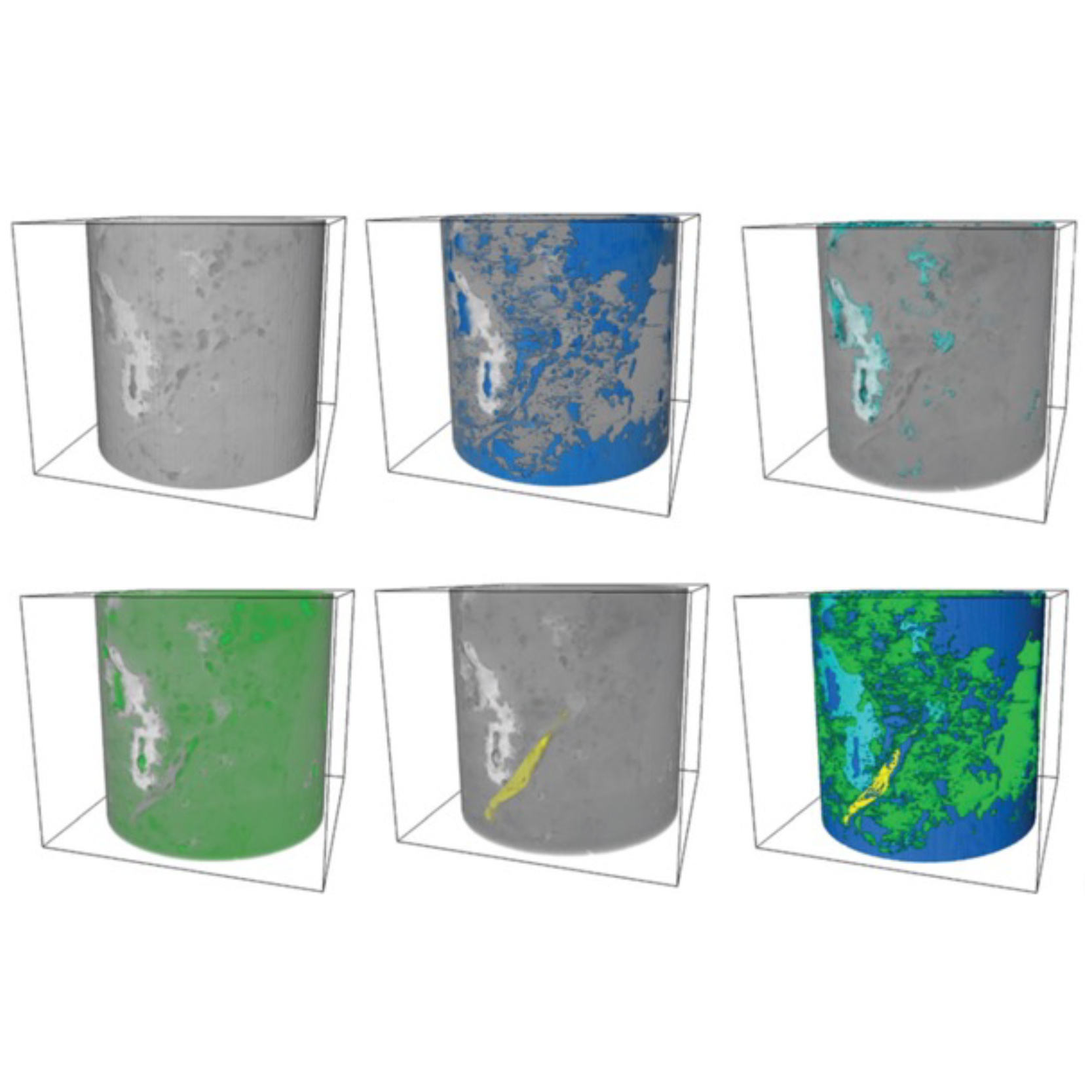

The scans allowed to determine the early stage of the main failure mechanisms involved in the tensile fracture process (Figure 1). The matrix cracking at the crack tip and a limited fiber failure were detected as well as the absence of any degradation mechanisms in the central part of the coupon’s ligament. Moreover, a post-mortem analysis of the compression specimens gave the possibility to study the failure process along the specimen’s width (Figures 2 and 3). The formation of wedge structures within the ligament and their evolution were observed as well as a widespread presence of delaminations.

The NXCT provided us the support in performing the micro-CT scan in the laboratory at the University of Southampton and provided a continuous cooperation.

Without the support of the X-ray CT images it would have not been possible to observe the early-stage damage mechanism at the crack tip in the tensile coupons. Furthermore, a full overview of the fracture zone in the compression specimens would have been impossible. In the future we plan to investigate the sub-critical failure mechanisms that anticipate the final fracture in compression specimens. Moreover, the study of alternative advanced thermoplastic composite systems is foreseen.

“The support from the µ-VIS X-ray Imaging Centre has been fundamental for the development of this study.

Future collaborations on this topic will guarantee a full understanding of the fracture process for advanced composite materials allowing for their full exploitation in safety-related applications.”

Federico Danzi

Investigator / Researcher

Figure 1: CT scan of double edge notched tensile specimens at 90% of ultimate tensile strength: (a) 20 mm wide geometry

front view in the specimen mid-plane, (b,c) 20 mm wide geometry through the thickness views, (d) 35 mm wide geometry

front view in the specimen mid-plane, (e,f) 35 mm wide geometry through the thickness views.

Figure 2: Fracture zone in a 10 mm wide double-edge notched compression specimen, after peak load.

Figure 3: Fracture zone in a 35 mm wide double-edge notched compression specimen, after peak load.

Soft magnetic elastomer membranes enable fast magnetic actuation under low fields. In our project, we… Read More

Nowadays, the increasing capability of micro-manufacturing processes enables the manufacture of miniature products with extremely… Read More

Injection of CO2 into shale reservoirs to enhance gas recovery and simultaneously sequester greenhouse… Read More