3D Microstructure of Soft Magnetic Elastomer Membrane

Soft magnetic elastomer membranes enable fast magnetic actuation under low fields. In our project, we… Read More

Events & Resources

News, Events and Resources from NXCT Partners

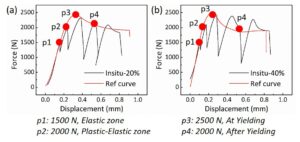

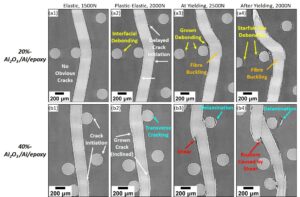

Metal reinforcements to polymer matrix composites (PMCs) provide enhanced architectural freedom and functional capabilities at low costs, however, weak interfacial bonding limits their applications.

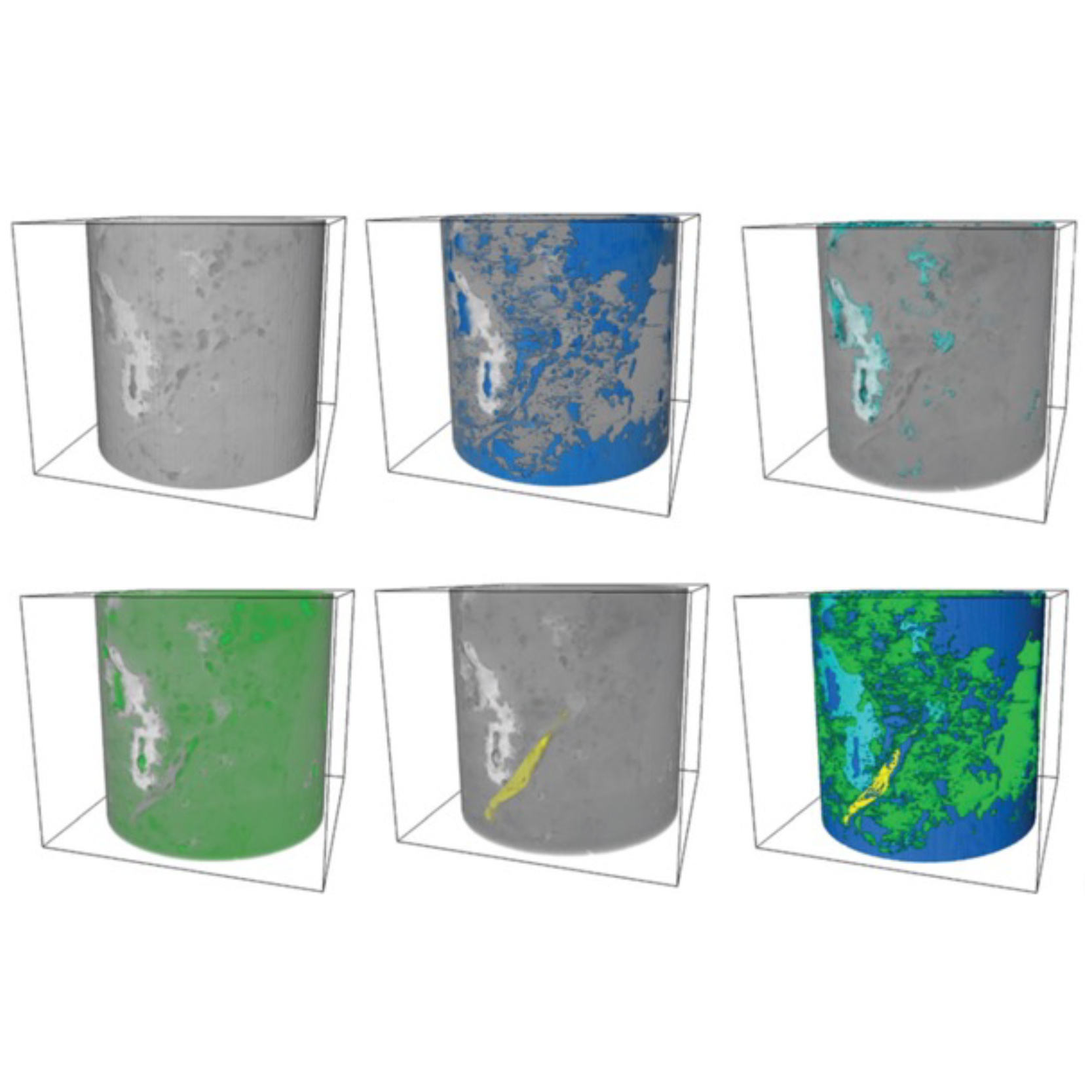

In our previous work, Plasma Electrolytic Oxidation (PEO) has been proven to be an effective way of preparing hybrid Al2O3-Al reinforcements to polymer matrix composites with enhanced flexural behaviour. However, to fully understand the mechanical behaviour and potential applicable areas, other mechanical properties also require further investigation. In this work, X-CT was employed to achieve an in-situ characterisation of γ-Al2O3/Al fibre of different oxide ratio inside the epoxy specimens (size: 5mm∙5mm∙4mm), which are subjected to a progressive compressive loading condition. The evolution from traditional destructive methodologies like cutting and grinding of failed samples is seismically significant. Traditional methods risk altering results and struggle to visualize internal fibre damage accurately. Dependencies on post-failure analysis assumptions also risk inaccuracies. X-CT though, overcomes these challenges, revealing a powerful means for insightful understanding of fibre damage evolution under compression. This research wouldn’t have been possible without the support of the NXCT team’s professionalism, patience, and dedication to both experimental design and X-CT data analysis. The use of Zesis-Versa650also ensured high-quality X-CT results. The scanner’s exceptional performance underpins the reliability of our findings. This research helps us to have an in-depth understanding about how damage initiate and develop within the ceramic-metal-polymer composites, which is not a well-understood terms. This could benefit the future design of such types of composites which can be applied in automobile, aerospace and navel industries.

Soft magnetic elastomer membranes enable fast magnetic actuation under low fields. In our project, we… Read More

Nowadays, the increasing capability of micro-manufacturing processes enables the manufacture of miniature products with extremely… Read More

Injection of CO2 into shale reservoirs to enhance gas recovery and simultaneously sequester greenhouse… Read More