3D Microstructure of Soft Magnetic Elastomer Membrane

Soft magnetic elastomer membranes enable fast magnetic actuation under low fields. In our project, we… Read More

Events & Resources

News, Events and Resources from NXCT Partners

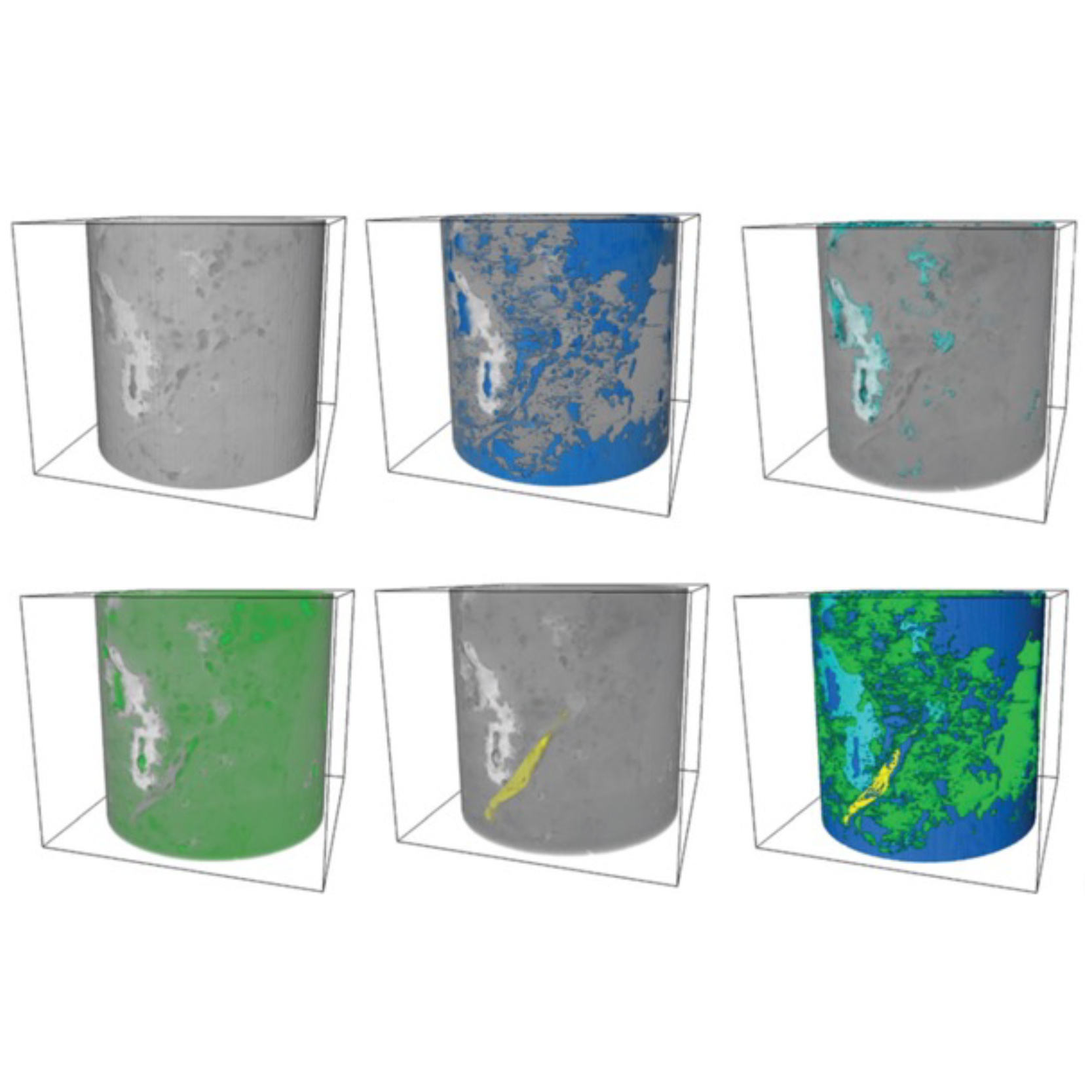

How accurately can metal additive manufacturing create complex periodic lattice structures in detail? Using X-ray CT to scan lattices samples we can create digital models. These digital models can be compared to the original used in manufacturing to highlight the differences between the CAD ideal and printed object.

The topology of a periodic lattice structure has a large impact on its bulk properties. Lattices are of interest because they can match the performance requirements of some solid materials in certain applications whilst saving weight and material. There are various techniques to evaluate their performance based on the designed topology. However, questions remain over the ability to accurately manufacture such a structure.

For this project a series of samples were manufactured based on the commonly used Body Centred Cubic (aka X) lattice topology. The samples contained 10x10x10 repeating units of the lattice arranged in a cube. With the aim to push the limits of the manufacturing capabilities, each lattice strut was designed to be just 1mm in diameter. The samples were additively manufactured at the Autodesk Technology Centre in Boston (USA) using 316L stainless steel powder in a Renishaw AM500Q.

The NXCT centre in Manchester provided beamtime access, technical expertise, and computing facilities to scan some of these samples and recreate a digital copy of one of them. On this digital copy we were able to locate possible powder remnants on the surface of the lattice and suggest areas with possible internal defects. More interestingly they were able to compare the scanned topology to the designed topology and quantify the differences.

This was a preliminary experiment to see what was possible with X-ray CT of lattice topologies. The results demonstrate the role that X-ray CT can play in the real-world implementation of lattice topologies. Given this success the other scanned lattice samples can be usefully analysed. As lattice technology becomes more prevalent in the industry, this work highlights the differences between our theoretical knowledge and our manufacturing capabilities.

Soft magnetic elastomer membranes enable fast magnetic actuation under low fields. In our project, we… Read More

Nowadays, the increasing capability of micro-manufacturing processes enables the manufacture of miniature products with extremely… Read More

Injection of CO2 into shale reservoirs to enhance gas recovery and simultaneously sequester greenhouse… Read More