3D Microstructure of Soft Magnetic Elastomer Membrane

Soft magnetic elastomer membranes enable fast magnetic actuation under low fields. In our project, we… Read More

Events & Resources

News, Events and Resources from NXCT Partners

Mon, 4 Sept 2023

The course is suitable for anyone with interest in x-ray imaging in life-sciences.

14:00 – 15:30 BST

Click here to sign up.

Many of us will have had the unpleasant experience of being stung by a bee. What we may not realise in that instant is the remarkable feat of evolution that the bee stinger constitutes.

When a bee stings the stinger comes away from the bee body and continues to sting autonomously. Its piercing parts move in a reciprocating motion, propagating the stinger deeper into tissue. At the same time, the motion of the piercing parts pump venom by moving a set of two collapsible pistons, also in a reciprocating fashion. This all happens fast and at a micro scale. Each piston has a stroke length of 600µm and a maximum speed of 2000µm/sec. This means that multiple pumping cycles are completed in a single second. Once detached from the body the stinger has no way to replenish its energy stores and motion rapidly decays. Stinging concludes at approximately 30 seconds to 2 minutes post detachment.

We set out to understand the kinematics and fluid flow patterns of this unusual micropump. We started by studying the 3D morphology of the stinger using microCT. We carried out segmentation using ITK-snap and used additional imagery from light microscopy and SEM to guide tissue interpretation. Resulting meshes were post?processed using a combination of MeshMixer and MeshLab. Cleaned meshes could then be 3D printed in rigid (PLA) or flexible materials (TPEs) to act as aids for interpretation of stinger kinematics. Finally, cleaned meshes were also incorporated in upscaled working model designs using Fusion360. These designs were 3D printed and used to replicate stinger pumping behaviours. Kinematics were replicated using measurements obtained from high-speed videography analysis. The stinger is challenging to observe and difficult to manipulate. The combination of microCT and 3D printing brings this system into the realm of tractable study.

Soft magnetic elastomer membranes enable fast magnetic actuation under low fields. In our project, we… Read More

Nowadays, the increasing capability of micro-manufacturing processes enables the manufacture of miniature products with extremely… Read More

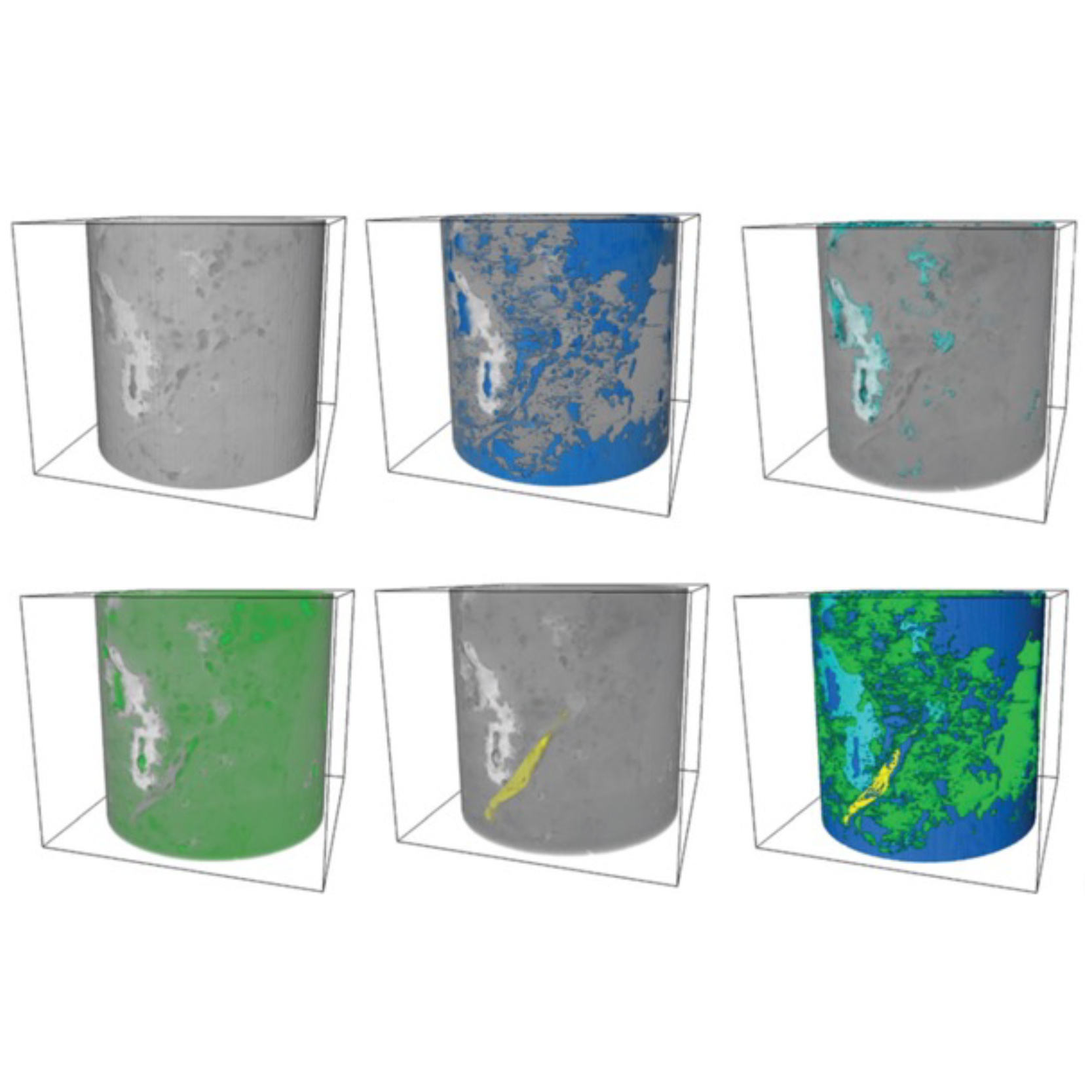

Injection of CO2 into shale reservoirs to enhance gas recovery and simultaneously sequester greenhouse… Read More