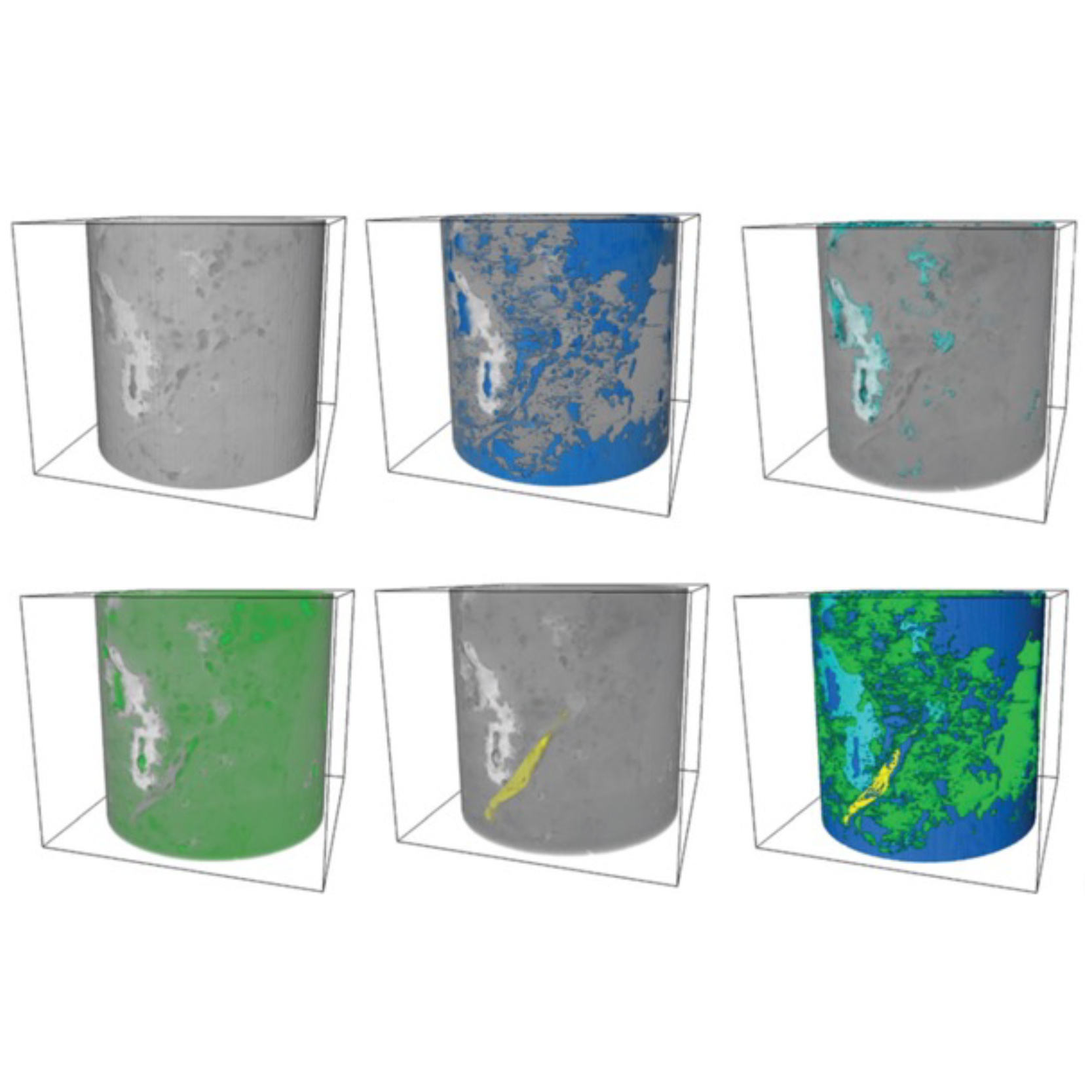

3D Microstructure of Soft Magnetic Elastomer Membrane

Soft magnetic elastomer membranes enable fast magnetic actuation under low fields. In our project, we… Read More

Events & Resources

News, Events and Resources from NXCT Partners

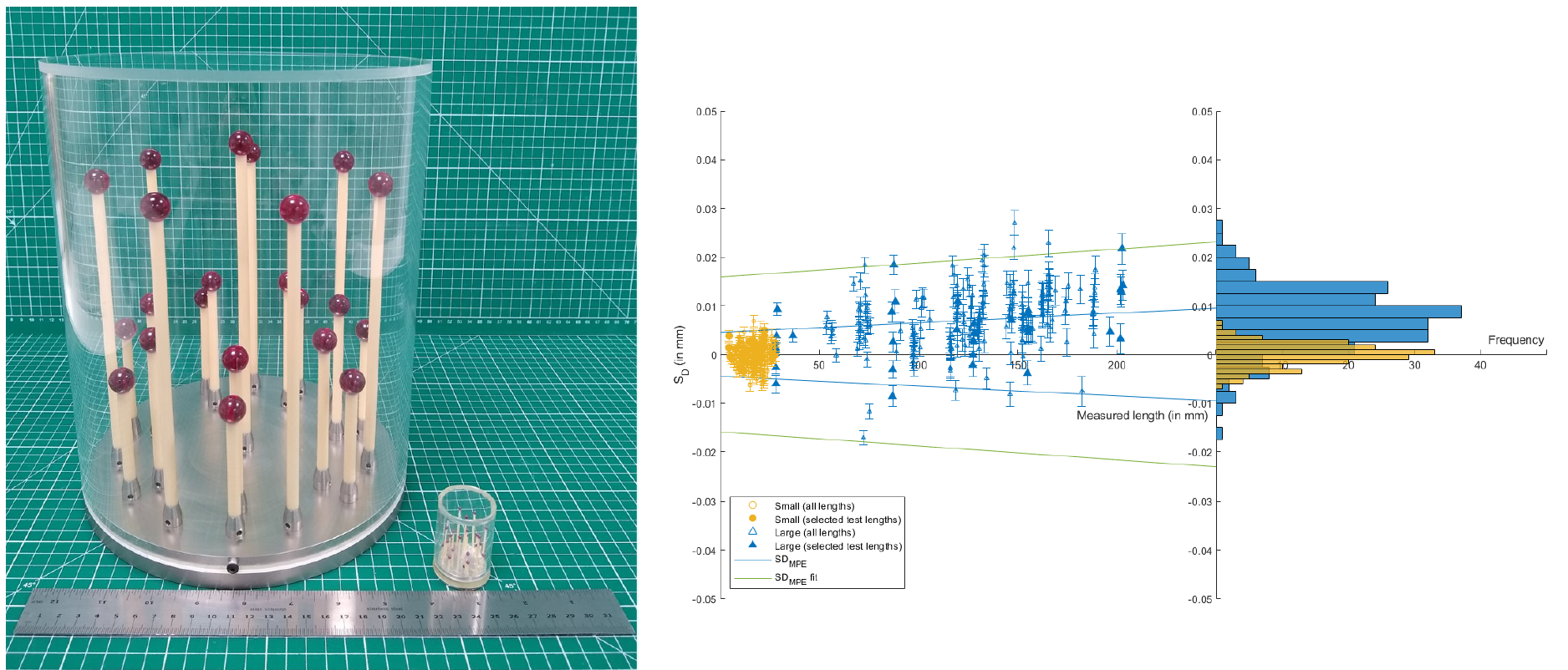

With the rise of dedicated Metrology X-ray CT systems, so have the expectation of the users to have the most accurate dimensional measurements. There has never been a cross system comparison that utilises the same object which makes any capability comparison difficult, which has been directly addressed in this project.

Some X-ray CT manufacturers have a dedicated “metrology” system, specifically designed to minimise dominating error sources resulting in the most accurate dimensional measurements. A barometer of performance is the “Maximum Permissible Error” (MPE) which provides an error bound on the test length being measured within any measurement volume of the system. The guideline for evaluating this is broadly agreed among manufacturers to be VDI/VDE 2630-1.3:2011 which has some requirements on which measurement volumes are used and magnitude and number of test lengths.

The latter is relatively vague which provides the flexibility for different workpieces to be used. This can sound advantageous but now each manufacturer has their own style of object, each with their own benefits and limitations making direct comparisons of MPE’s impossible. In this study two calibrated work pieces were scanned according to the guideline across five different manufacturers systems. The workpieces themselves were ruby sphere “forests”, where one was a scaled version of each other for the extreme measurement volumes.

NXCT enabled access to a variety of manufacturer machines, where not all were available at one site which is its strength. In particular, the metrology expertise at Warwick supported the experimental design and implementation to ensure the fair comparison we desired.

As a result, the metrology and X-ray CT community now have a complete understanding of the dimensional measurement performance of these types of dedicated systems which they previously didn’t have. Further it sets a benchmark for manufacturers to work from to enhance their offerings as NXCT continues to work closely with them. Moving forward it would be good understand the long term stability of the metrology systems vs their non-metrology counterparts and will continue to work with Warwick and the wider NXCT to enable this.

“This work has provided a fair representation of the dimensional measurement capability of X-ray CT to the community. The previously stated MPEs have appeared to be a little tight when considering the extremes of the measurement volume, although the results in the best performing systems are still very strong with sub-pixel level accuracy. This method is open, with a full description of our object and we look forward to others exploiting this as their metrology systems improve with time.”

Evelien Zwanenburg, PhD Researcher, University of Warwick

Left: The large and small ruby sphere forest

Right: Exemplar results from one of the metrology systems with distance error (mm) against test length (mm).

Soft magnetic elastomer membranes enable fast magnetic actuation under low fields. In our project, we… Read More

Nowadays, the increasing capability of micro-manufacturing processes enables the manufacture of miniature products with extremely… Read More

Injection of CO2 into shale reservoirs to enhance gas recovery and simultaneously sequester greenhouse… Read More