3D Microstructure of Soft Magnetic Elastomer Membrane

Soft magnetic elastomer membranes enable fast magnetic actuation under low fields. In our project, we… Read More

Events & Resources

News, Events and Resources from NXCT Partners

Phase-change materials must melt and freeze reversibly, reliably, and reproducibly thousands of times to be useful for thermal–energy storage, important for balancing supply and demand as reliance on renewable energy generation grows. Understanding of their crystallisation behaviour is key to producing novel, high–quality PCMs.

Thermal-energy storage is an important technique to combat misalignment in energy supply and demand, which will only grow greater as we transition to using more renewable energy generation. 49.7% of the UK’s overall energy usage in 2021 was for heating applications. Sunamp is a world leader in thermal-energy storage, using high energy density phase-change materials (PCMs) to store large amounts of energy over a small temperature swing in very compact “heat batteries”. Many of the PCMs used are based on salt hydrates. Understanding their crystallisation behaviour is very important for formulation optimisation and enclosure design.

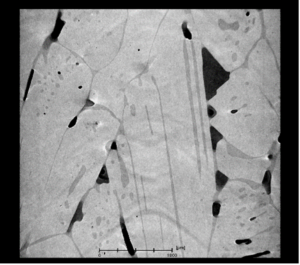

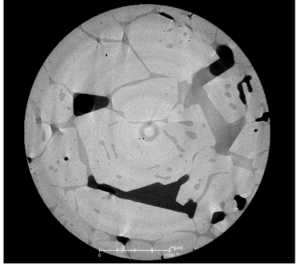

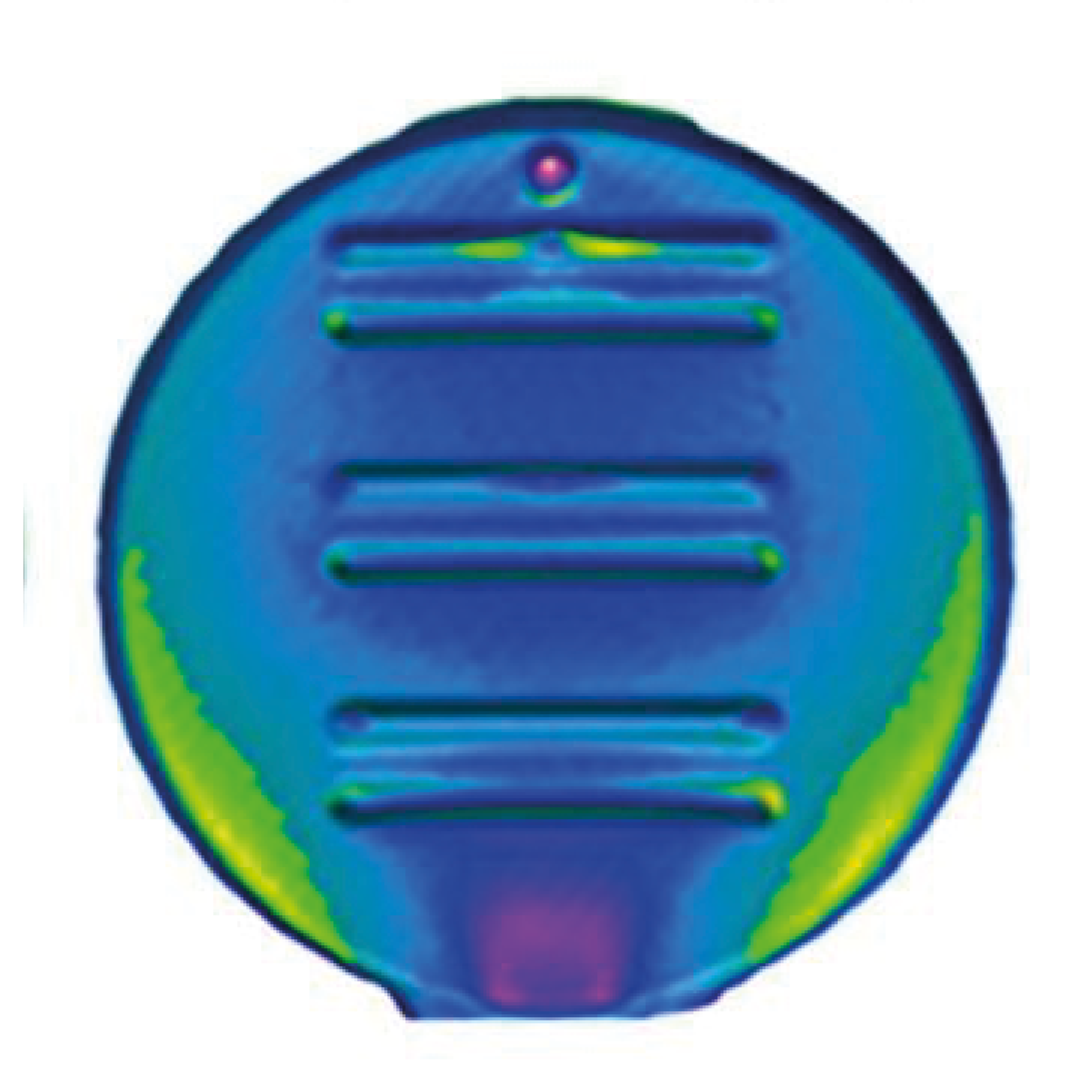

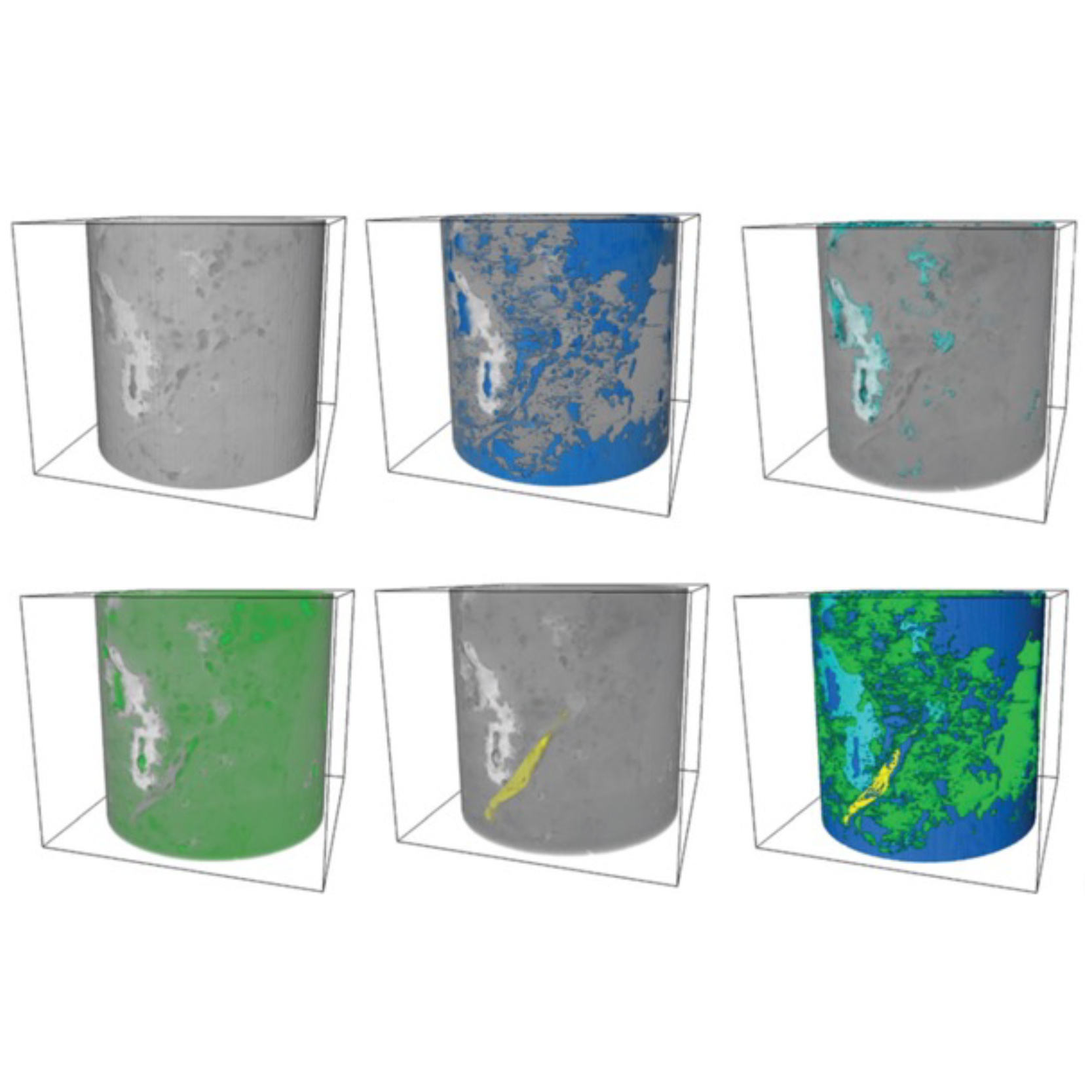

Direct observation of PCM samples (both single-salt and eutectic) treated in different ways would give a better understanding of nucleation and crystallisation of the phases and identify air voids in the bulk. This could inform the optimisation of cycling conditions for different formulations, and so maximise each PCM’s performance. The information could also be used to improve system modelling and design.

The NXCT’s programme for SMEs awarded three days of beamtime and two days of analysis time at the facility at the University of Manchester. High-resolution data from PCM samples was collected, meaning that, for the first time, crystals throughout a bulk sample could be mapped and measured. Differences in crystallisation in samples nucleated at different temperatures could be quantified, and any segregation of phases in the eutectic mixture could be observed.

The research will help in the design of Sunamp’s new materials and heat batteries, and further the knowledge in the field of crystallisation behaviour of single- and mixed-phase salt hydrates. In the future we hope to collect data for molten PCM systems, to observe and identify phases that do not melt under normal operating conditions.

Samples of crystalline PCM, clearly showing crystal boundaries and air voids

“Access to the CT scanning facilities has been fantastic for us to gain a better understanding of the crystallisation processes in our materials. This information can be fed back into the design of our products. Plus, we have some fantastic images from the beamtime that we can show to non-chemists to help them understand the work we do better.”

Dr Emily Goddard, Sunamp, Materials Research Chemist

Soft magnetic elastomer membranes enable fast magnetic actuation under low fields. In our project, we… Read More

Nowadays, the increasing capability of micro-manufacturing processes enables the manufacture of miniature products with extremely… Read More

Injection of CO2 into shale reservoirs to enhance gas recovery and simultaneously sequester greenhouse… Read More